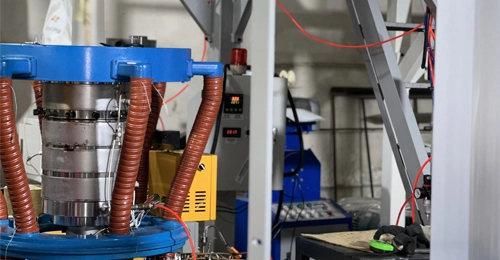

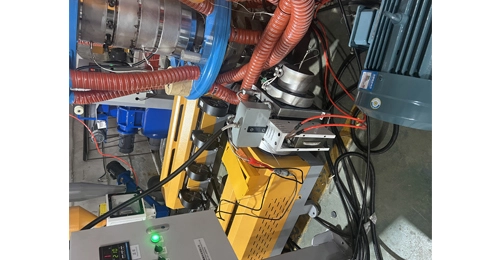

Our ABA film blowing machine is designed for efficient production of polyethylene films (LDPE, HDPE). Ideal for applications like packaging, agriculture, textiles, and clothing, our machine offers precise control and energy efficiency. The frequency-controlled main motor ensures stable operation and reduced power consumption. The lifting-type traction frame optimizes film cooling for superior quality.

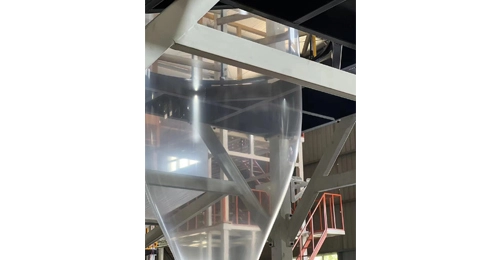

To achieve consistent results, our film blowing process involves precise feeding, heating, traction, and pressure control. The air-filled blow hole inflates the film, allowing for adjustable bag sizes. Our film stabilizer ensures even thickness and stability.

Our ABA machine, also known as a fake three-layer machine, features a unique three-layer die head. This design enables the production of high-quality films by combining a filler layer with new materials, resulting in improved properties and cost-effectiveness.