- > Search By Functions

- > Co-Extrusion

- > Search By Material

- > Search By Machines

- > Search By Machines

- > Search By Machines

What are you looking for?

The extruder, cylinder and screw are alloy steel, tight nitride treatment and precision machining, with high hardness and corrosion resistance, specially designed screw with high yield, good plasticity, suitable for blowing low density polyethylene (LDPE) high density polyethylene (LLDPE) plastic film, widely used in food, clothing, garbage bags, vest bags and other civil and industrial packaging.

MODEL | GL35-350 Mimi Bblower | |

Screw diameter | ¢35 | |

Screw ratio L/D | 28:1 | |

Screw material | 38CrMoAl | |

processing technic | Positive ight-conditioning-eliminate stress-nitride | |

Maximum screw rotation speed | 100M/MIN | |

Number of cylinder heating areas | 3 District | |

Heater form | Stainless steel double-layer heater | |

structural style | Coat with stainless steel heating ring | |

Speed reduction box material | Use hard tooth gear box | |

Die diameter | 30mm (one) | |

calorifier | Stainless steel double-layer heater | |

Machine head material | 45 # Head inner channel plated hard chrome | |

material | Aluminum wind ring (Wind cooling | |

steel frame constrution | Safety operation platform and safety guardrail are provided | |

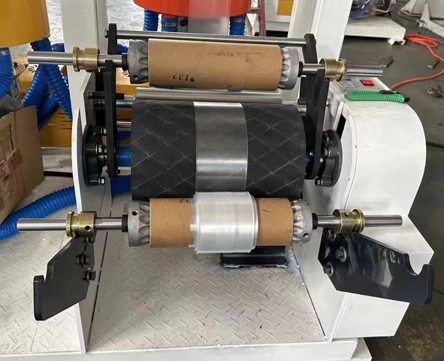

Traction roller length | Rubber roller | |

Human board device material | Wooden structure frame | |

Maximum Angle | 22 Degrees (Adjustable) | |

Traction roller length | 350MM | |

Traction roller material | acrylonitrile-butadiene | |

Form of receipt | Friction type single volume | |

Wrapping motor | Torque speed adjustment motor | |

Electrical appliance control system (self-energy temperature control table) | ||

Total work rate | About 5KW | |

power consumption | 1.5KW | |

weight | About 1T | |

Effective blow film specification | ||

Blow width | 50-250MM (diameter) | |

film thickness | 0.01-0.12 mm | |

Applicable raw materials | PE | |

Steel frame with platform,security guardrail | ||

The tower is made of column square tube. Platform uses section steel, with insert tread on it, Ladder equipped with banisters connected by bolt. | ||

Electronic control cabinet mainly controls the processing temperature, screw speed, film linear speed, cooling fan, winder and so on. | ||

Main engine、take up、blower、 | ||

Digital display intelligent temperature controller is adopted | ||

The temperature control system adopts a solid-state module | ||

Contactors by chint brand. | ||

Provide the internal connection cable of the unit | ||

Tool box | 1box | |

Die head adjusting screw | 1set | |

use | The unit extruder, cylinder and screw are made of high quality alloy steel, tight nitride treatment and precision processing, with optimal hardness and corrosion resistance, high yield of special design screw and good molding.It is suitable for blowing low density polyethylene (LDPE) high density polyethylene (HDPE) linear low density polyethylene (LLDPE) and other plastic films, widely used in food, clothing, garbage bags, vest bags and other civil and industrial packaging. | |