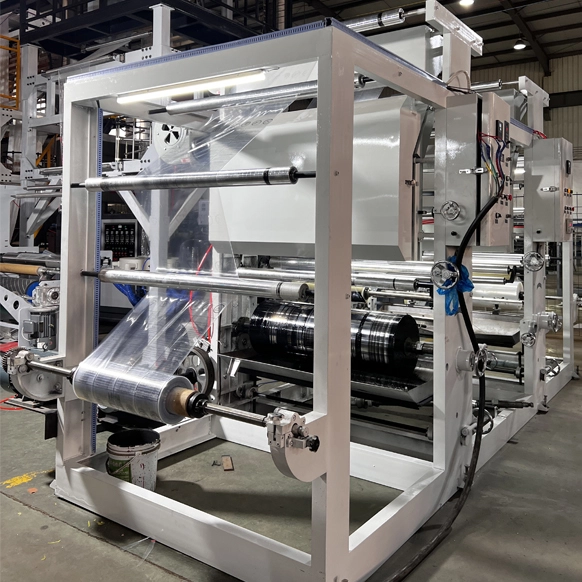

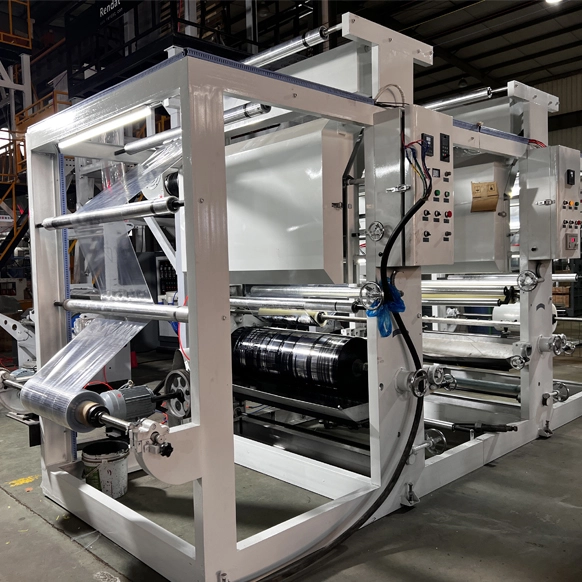

1. Ink supply system: it is responsible for supplying the ink to the concave plate used in the printing process, including the ink groove, ink roller and scraper components, to ensure that the appropriate amount of ink is transmitted to the groove of the concave plate.

2. Plate: It is a key part of the printing process. It is a metal or polymer plate with grooves, and the shape and depth of the grooves determine the final printed pattern or text.

3. Printing roller: the parts that transfer the ink from the concave plate to the printing material, through the contact with the concave plate, to transfer the ink from the groove, and evenly spread on the printing material.

4. Scratcher: used to scrape the excess ink on the surface of the concave plate, only retain the ink in the groove, usually made of rubber or plastic, to ensure the smoothness of the concave plate surface and the accurate delivery of the ink.

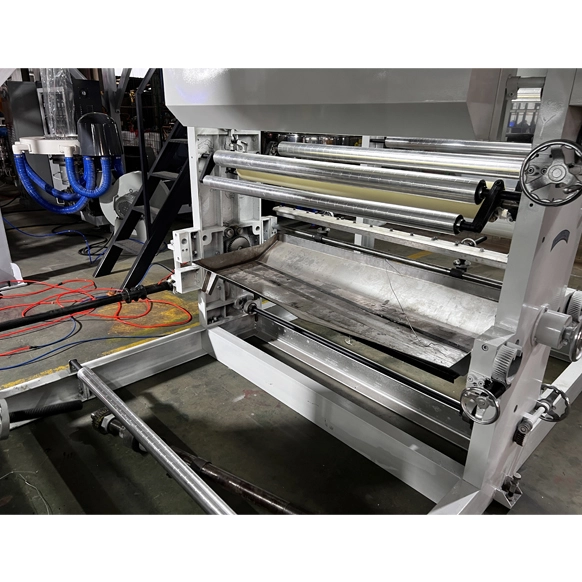

5. Transmission system: responsible for sending printing materials from the feeding end into the printing press, and then removed from the discharging end after the printing process, including feeding device, tensioning device, guide device and rewinding device, etc.