- > Search By Functions

- > Co-Extrusion

- > Search By Material

- > Search By Machines

- > Search By Machines

- > Search By Machines

What are you looking for?

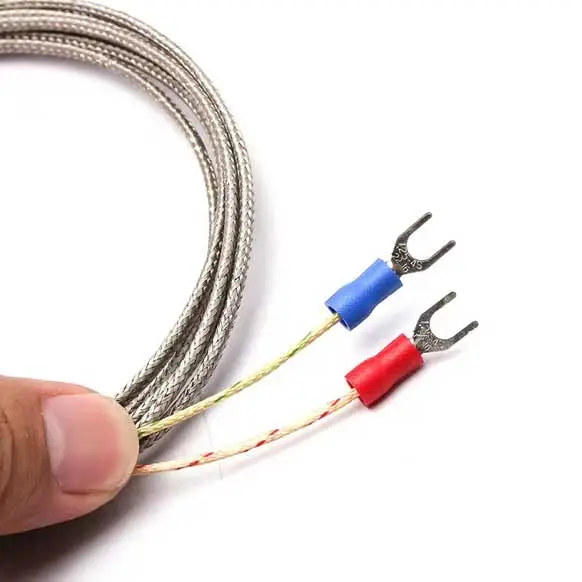

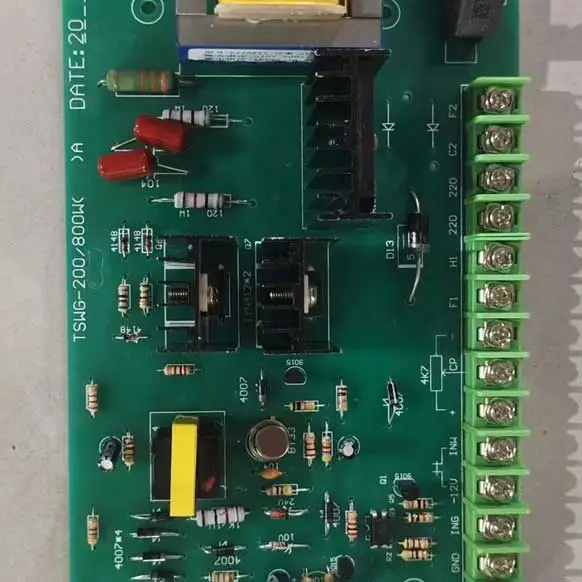

Spare Parts comprise a wide range of essential components necessary for the maintenance and repair of machinery. These components include devices like Corona Treaters for surface treatment, Heaters for providing heat, Screws as basic mechanical parts, Air Rings used in film blowing, Temperature Controllers for regulating temperature, Extruder Filters for filtering impurities, Thermocouples for temperature measurement, Speed Controllers for adjusting machine speed, Photoelectric Switches as light sensors, Pelletizer Knives for cutting in pelletizing, and Solid State Relays for electronic switching.

1. Object detection: The photoelectric switch can detect the presence or absence of objects in the processing line. It provides inputs to the control system, allowing the equipment to automatically initiate or stop specific processes based on the presence or absence of objects. This eliminates the need for manual intervention, increasing efficiency and reducing errors in the operation.

2. Position control: Photoelectric switches can also precisely detect the position of objects, such as the position of the plastic material or moving parts. This information can be used to regulate the speed or timing of different processes, ensuring accurate positioning and alignment. This contributes to the precise and consistent production of plastic components or products.

3. Quality control: The photoelectric switch can be used to monitor the quality of the plastic material or the finished product. By detecting certain characteristics or defects, such as color, transparency, or shape, the switch can trigger alarms or corrective actions. This helps in maintaining consistent product quality and prevents defective items from entering the production flow.

A Corona Treater works by applying a high-voltage electric discharge to the surface of plastic materials. This discharge alters the surface energy, enhancing the adhesion of inks, coatings, or adhesives to the plastic substrate.

A Heater is commonly used in plastic machinery equipment for processes such as extrusion, injection molding, and blow molding. It provides the necessary heat to melt and shape the plastic material.

In plastic extruders, a Screw is responsible for feeding, melting, and conveying the plastic material. It helps in achieving uniform melt and pressure buildup for shaping or processing.

A Die Head in plastic machinery equipment shapes the plastic material into the desired form. It controls the flow and distribution of the molten plastic, allowing for precise shaping and sizing of the extruded product.