Express bag blowing machine is a commonly used plastic bag equipment, mainly used for the production of all kinds of plastic express bags. This paper will introduce the equipment process principle of the express bag film blowing machine.

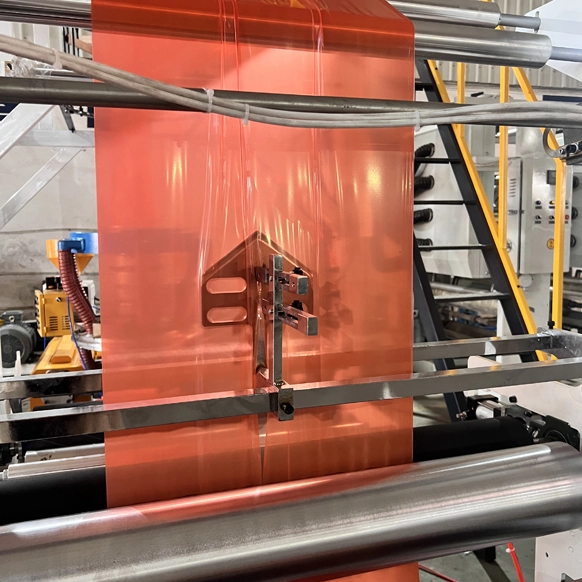

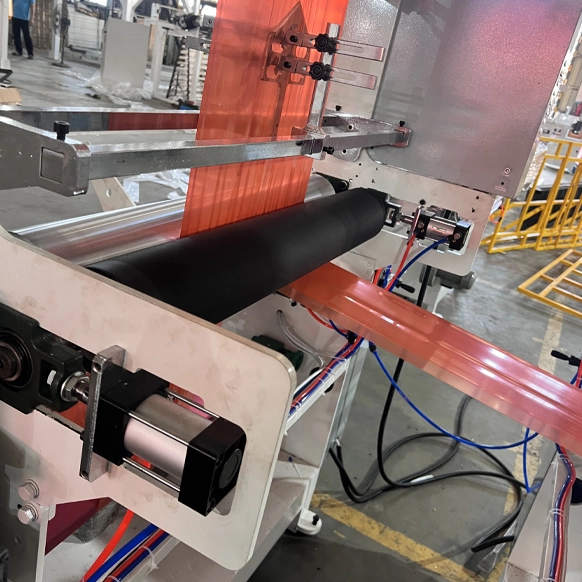

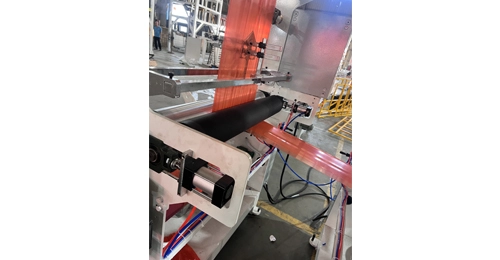

Express bag film blowing machine is a kind of extrusion film blowing machine equipment, its main components include: feeding system, extruder, mold head, cooling system, winding, electrical system, etc. Among of the most important is the extruder and die head.