- > Search By Functions

- > Co-Extrusion

- > Search By Material

- > Search By Machines

- > Search By Machines

- > Search By Machines

What are you looking for?

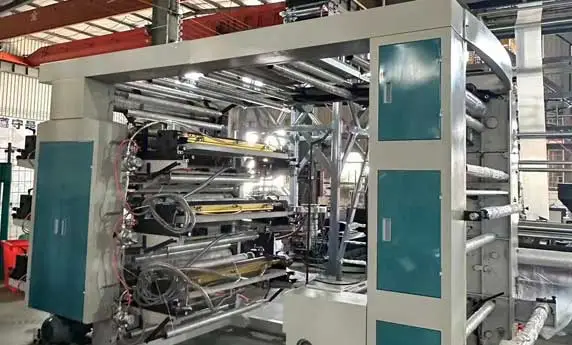

Ruian City GuoLian Machinery Co., Ltd. is a renowned manufacturer of plastic machinery and equipment, with a focus on packaging machines. Our extensive product line includes over 50 varieties, such as high blown film units, two-color film blowing machines, automatic bag sealing machines, and high-speed precision slitters. Our innovative computer-controlled sealing and bagging systems set us apart in the industry. Our products are widely used domestically and exported to over 40 countries worldwide, demonstrating our global reach and trusted quality.

The future of film blowing machines in the packaging industry looks promising, with advancements and trends shaping their development in various ways:

1. More Sustainable Materials: The future of packaging leans towards sustainability, and film blowing machines are expected to accommodate the growing demand for eco-friendly materials. This includes the development of biodegradable films, compostable materials, and the use of recyclable plastics to reduce environmental impact.

2. Advanced Automation: Film blowing machines will continue to integrate advanced automation technologies, such as robotics and artificial intelligence. These advancements will improve efficiency, minimize human error, and optimize production processes by allowing for real-time monitoring and adjustments.

3. Improved Energy Efficiency: Energy consumption is a significant concern, and future film blowing machines will focus on enhancing energy efficiency. Innovations in heating technologies and heat recovery systems will reduce energy consumption and lower production costs, making them more economical and environmentally friendly.

4. Smart Packaging Capabilities: The rise of smart packaging presents new opportunities for film blowing machines. These machines will enable the production of packaging with integrated sensors, indicators, and tracking capabilities. This functionality will provide real-time monitoring of product freshness, temperature changes, and even potential spoilage, enhancing product safety and consumer experience.

5. Customization and Personalization: With increasing consumer demand for unique and personalized products, film blowing machines will offer greater flexibility and customization options. This includes the ability to produce films with various colors, textures, patterns, and even printed designs, allowing brands to stand out on the retail shelf and cater to individual preferences.

Overall, the future of film blowing machines in the packaging industry holds exciting possibilities. Sustainability, automation, energy efficiency, smart capabilities, and customization are expected to shape their development and contribute to advancements in packaging technology.

Proper maintenance is crucial for ensuring the efficient and reliable performance of packaging machines. Here are some key tips to help you maintain your packaging machines:

1. Regular Cleaning: Regularly clean your packaging machines to remove any buildup of dust, debris, or leftover materials. This helps prevent contamination and ensures smooth operation.

2. Lubrication: Proper lubrication of moving parts is essential to reduce friction and wear. Follow the manufacturer's guidelines for lubricating specific components, such as belts, chains, gears, and bearings. Use recommended lubricants and apply them at the recommended intervals.

3. Inspections and Repairs: Conduct routine inspections to identify and address any issues or potential problems with the packaging machine. Check for loose connections, worn out parts, or signs of damage. Promptly repair or replace any faulty components to prevent further damage or breakdown.

4. Calibration and Adjustment: Regularly calibrate and adjust the settings of your packaging machine to ensure accurate and consistent performance. This includes checking temperature settings, pressure levels, speed, and other parameters. Follow the manufacturer's instructions for calibration procedures.

5. Operator Training: Properly train and educate the operators who work with the packaging machines. They should understand the machine's operation, maintenance requirements, and safety protocols. Encourage operators to report any abnormalities or unusual sounds that they notice during operation.

By following these maintenance practices, you can extend the lifespan of your packaging machines, minimize downtime, and ensure maximum productivity and efficiency in your packaging operations.