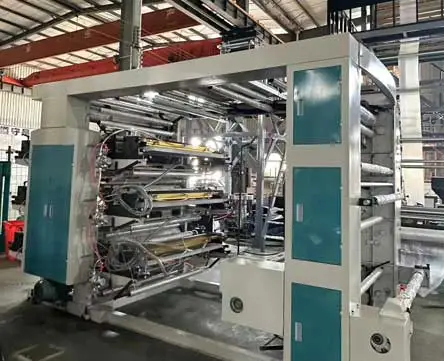

The principle of the flexographic printing press

A flexible printing press is a printing device that is commonly used to produce high-quality images of a variety of materials. Its principle is to use elastic flexible plate material, so that the printed plate and printed material contact and transfer the image. In simple terms, the flexo printing press uses the bulge on the printed plate to transfer the corresponding image to the printed material.

The main principle of this printing method is to make a flexible plate, the printed plate is in close contact with the printing material, and then the bulge on the printing plate is used to transfer the paint or ink to the bulge or hole on the printing material to form an image.

The flexible printing press uses the liquid fluid ink from the ink bucket roller and the mesh ink roller to the graphic part of the printing plate and makes the ink, and then applies the printing pressure from the press roller to transfer the ink on the printing plate to the substrate, and finally the printing process 2 is completed through the drying surface. This printing method combines the short ink conveying system and specific printing components, such as two ink rollers or even one ink roller with ink scraper, realizing the uniform and quantitative transfer of ink from ink to the surface of the printing plate 3. In addition, the flexo printing press also uses the mesh ink transfer roller transfer ink to complete the printing process, which has the advantages of simple structure, good rigidity and wide range of adaptation